Custom Hydraulic Cylinders for Offshore LNG Mooring System

Client: Offshore LNG Project, West Africa

Delivery: 12 Cylinders, Φ600mm x 4500mm Stroke

Industry: Marine & Offshore

Delivered by: Yangzhou Jiangdu Yongjian Co., Ltd.

Project Background

A floating liquefied natural gas (FLNG) production and storage vessel operating off the coast of West Africa required 12 large-scale, custom-designed hydraulic cylinders for its mooring tensioner system. These cylinders play a critical role in maintaining vessel stability under harsh offshore conditions.

The client needed a partner with proven expertise in designing and delivering large-diameter hydraulic cylinders capable of operating for decades in highly corrosive marine environments. Yongjian was selected for its extensive experience, technical capabilities, and commitment to customized hydraulic solutions.

Engineering Challenges

The FLNG system required horizontally installed cylinders with large strokes and built-in accumulators, operating at a working pressure of 230 bar. These cylinders had to withstand:

Continuous exposure to seawater

Impact from floating debris and offshore equipment

Sand and dust carried by ocean winds

30+ years of operation without major failure

Each cylinder featured:

Bore diameter: 600mm

Stroke: 4500mm

Material: Carbon steel body, stainless steel piping

Additional features: Integrated accumulators, advanced manifold blocks

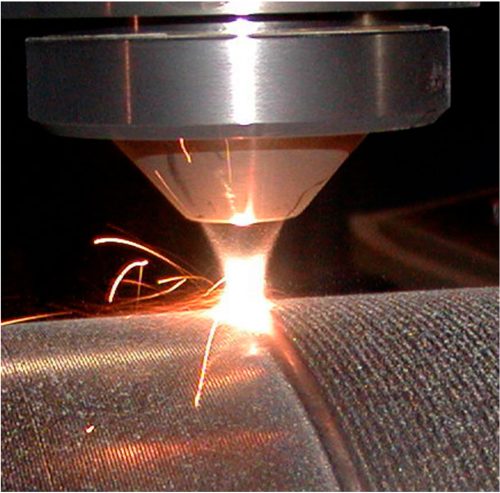

Corrosion Protection Solution

To ensure long-term reliability, Yongjian applied an advanced laser-cladded anti-corrosion coating on the cylinder rods. This proprietary solution offers exceptional resistance to corrosion, impact, and abrasion—ideal for marine conditions. Unlike traditional coatings, it forms a dense metallurgical bond with the rod, preventing peeling, cracking, or delamination.

The coating is also field-repairable, minimizing downtime and maintenance costs over the cylinder’s lifespan. Its proven performance has been validated in multiple offshore deployments.

Manufacturing & Delivery

Yongjian’s engineering team worked closely with the client to complete the design and delivery within 10 months. The project was manufactured and tested in our state-of-the-art facility in Jiangsu, China, supported by skilled technicians and rigorous quality inspection protocols.

Result & Value

Our custom solution provided:

Enhanced reliability and corrosion resistance

Simplified maintenance with field-repairable rods

Increased project safety and uptime

Lower total cost of ownership

Yongjian’s cylinders now contribute to the stable mooring and long-term performance of one of West Africa’s key offshore LNG facilities.

Add comment